CUSTOM ORDER DRILL BITS

Industrial Grade Tools for OEMs & Distributors

PROFESSIONAL DRILLING SOLUTIONS

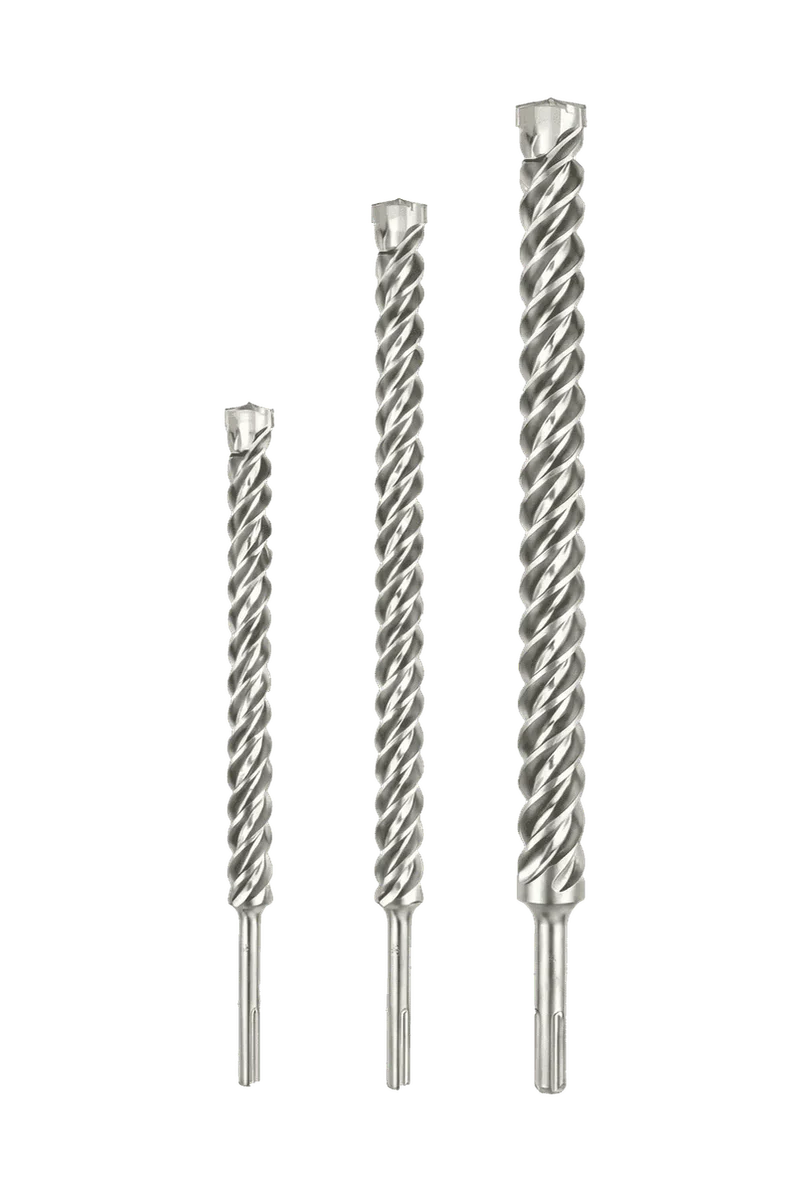

SDS-Plus Professional Series

High-performance drill bits designed for precision drilling in concrete, masonry, and stone. Features advanced carbide tips and optimized flute design.

TECHNICAL SPECIFICATIONS

INDUSTRY APPLICATIONS

SDS-Max Heavy-Duty Series

Heavy-duty drill bits designed for large-diameter drilling in reinforced concrete and masonry. Excellent performance in demanding applications.

TECHNICAL SPECIFICATIONS

INDUSTRY APPLICATIONS

Hammer Chisels

Comprehensive demolition tool series including point chisels, flat chisels, and scraping chisels for professional construction applications.

TECHNICAL SPECIFICATIONS

INDUSTRY APPLICATIONS

COMPLETE PRODUCT RANGE

Explore our comprehensive range of professional drilling tools designed for every application.

SDS-Max Series

Engineered for heavy-duty demolition and drilling. The preferred choice for large diameter holes in reinforced concrete.

Compatible with Industry-Leading Brands

Professional alternative solutions for major tool systems

Quality Assurance

Zero-Defect Protocol

Our manufacturing processes strictly adhere to our proprietary 12-point quality management system

CE Certification

All products comply with European safety and environmental standards

Quality Testing

Every batch undergoes rigorous testing for hardness, wear resistance, and structural integrity

At Zhonghuan Tools, quality is not just a priority—it's our foundation. Our commitment to excellence ensures reliable performance of every tool in the most demanding applications.

Precision Engineering Since 2008

Founded in 2008, Zhonghuan Tools has grown from a small workshop in Wenzhou to become one of China's leading manufacturers of professional concrete drilling tools, setting new standards for precision and reliability.

With over 20,000 square meters of advanced manufacturing facilities and a team of senior technical engineers, we produce over 10 million products annually for customers in more than 60 countries worldwide.

Our commitment to quality is unwavering. Every product undergoes rigorous testing to ensure it meets the highest standards of performance and durability in real-world applications.

Competitive Advantages

Zero-Defect Quality Standard

Trust and reliability for B2B customers

24-Hour Quote Response

Fast market response for urgent projects

Seamless English & Chinese Service

Better communication and understanding

OEM/ODM Specialization

Higher profit margins and customer loyalty

Advanced Manufacturing

20,000+ sqm facility with cutting-edge technology

Advanced Manufacturing Capabilities

State-of-the-art production facilities and advanced equipment ensuring consistent quality and high-volume manufacturing capacity.

4-Step Precision Manufacturing Process

Raw Material Processing

Premium Thermo-Lock™ alloy bars are precisely cut and prepared using advanced CNC machining centers with ±0.05mm tolerance.

Carbide Tip Assembly

German carbide tips are bonded using computer-controlled vacuum brazing furnaces ensuring uniform aerospace-grade joint strength.

Heat Treatment

Computer-controlled heat treatment processes ensure optimal hardness (HRC 58-62) and metallurgical properties.

Precision Grinding

Professional CNC grinders precisely grind spiral flutes for optimal chip removal and drilling efficiency.

CNC Machining Centers

Our 40 high-precision 5-axis CNC machining centers form the backbone of production. Each machine delivers ±0.05mm tolerance for steel body processing, shank preparation, and complex geometries—ensuring every drill bit starts with perfect dimensional accuracy.

Computer-Controlled Vacuum Brazing

Unlike common high-frequency welding, we utilize a fully automated vacuum brazing furnace. This process eliminates impurities and ensures every single carbide tip is bonded with maximum, uniform strength, providing a level of reliability that manual welding simply cannot match.

Heat Treatment Furnaces

Computer-controlled vacuum heat treatment furnaces precisely control hardness profiles. Our automated quenching systems achieve HRC 58-62 consistency across millions of units, ensuring predictable performance in the field.

Precision Grinders

Professional CNC grinders with diamond wheels precision-grind spiral flutes for optimal chip evacuation. Our proprietary flute geometry reduces drilling friction by 23%, extending tool life and improving penetration speed.

Quality Inspection Lab

Our metrology lab features coordinate measuring machines (CMM), hardness testers, and automated optical inspection. Every batch undergoes 12-point verification—achieving a 98.5% first-pass quality rate.

Smart Packaging Lines

High-speed automated packaging lines handle 30,000+ units daily with custom branding capabilities. Integrated QR tracking provides full traceability from raw material to delivery—supporting OEM partners worldwide.

Request a Quote

Our team will provide a detailed quote within 24 hours of receiving your inquiry.